Electric pallet stackers are versatile and efficient machines that can help streamline your warehousing operations. These machines are designed to lift and move pallets of goods, making them an essential tool for businesses that need to move large quantities of products quickly and efficiently. If you’re in the market for a new pallet stacker, it’s important to understand the different types of stackers available and how they can benefit your business.

One of the key benefits of electric pallet stackers is their operational efficiency. These machines are designed to be easy to operate and require minimal maintenance, which means that your team can focus on other tasks. Additionally, electric pallet stackers are highly maneuverable, which makes them ideal for use in tight spaces or narrow aisles. This can help you maximize your warehouse space and increase your overall efficiency.

Another important consideration when purchasing an electric pallet stacker is safety and controls. These machines are designed with safety in mind, with features like emergency stop buttons and automatic braking systems. Additionally, many electric pallet stackers come with advanced controls that allow operators to easily adjust the speed and direction of the machine, helping to prevent accidents and injuries. By investing in a high-quality electric pallet stacker, you can help ensure the safety of your team and your products.

Key Takeaways

- Electric pallet stackers are versatile and efficient machines that can help streamline your warehousing operations.

- Operational efficiency is one of the key benefits of electric pallet stackers, as they are easy to operate and highly maneuverable.

- Safety and controls are also important considerations when purchasing an electric pallet stacker, as these machines are designed with features that help prevent accidents and injuries.

Call our team on (02) 7209 0601

Get A Quote NowUnderstanding Electric Pallet Stackers

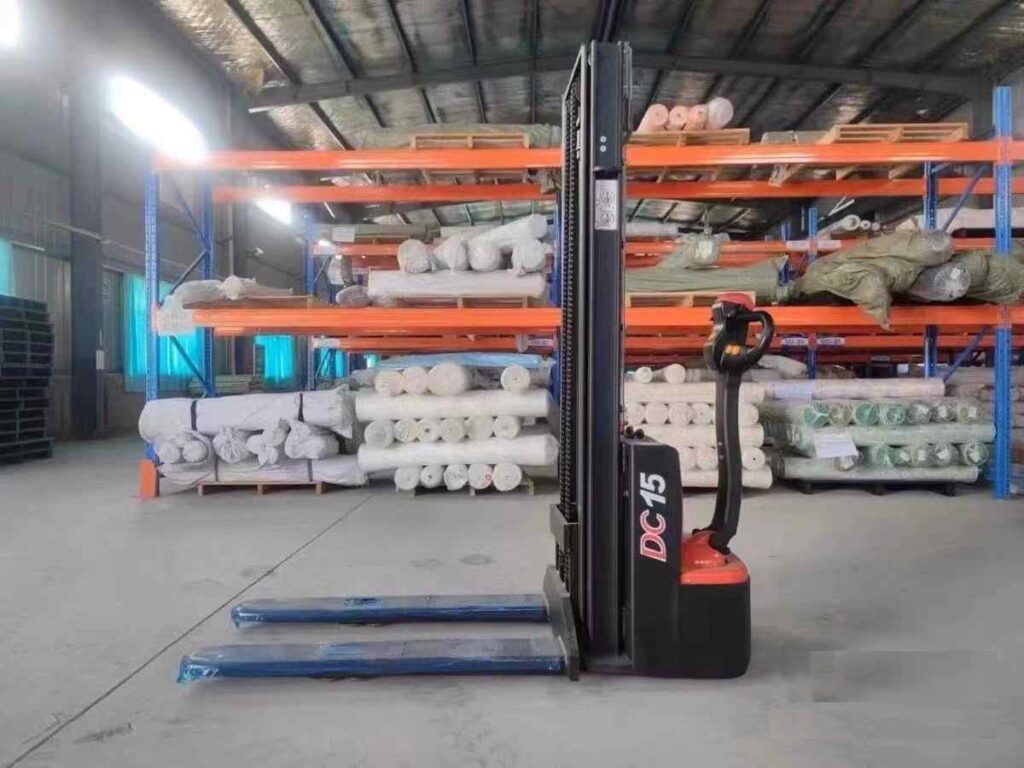

Electric pallet stackers are materials handling equipment that have revolutionized the way pallets are moved and stored in warehouses and manufacturing facilities. They are designed to simplify the process of moving and stacking pallets, and are powered by rechargeable batteries. In this section, we will discuss the fundamentals of electric pallet stackers, the types of electric pallet stackers available, and their capabilities.

Fundamentals of Electric Pallet Stackers

Electric pallet stackers are designed to move pallets around the warehouse or manufacturing facility. They are equipped with forks that slide under the pallet and lift it off the ground. The pallet is then moved to the desired location and lowered to the ground. Electric pallet stackers are designed to be easy to use and maneuverable, making them ideal for use in small spaces.

Types of Electric Pallet Stackers

There are several types of electric pallet stackers available, including counterbalance stackers, walkie stackers, and rider stackers. Counterbalance stackers are designed to lift heavy loads and are ideal for use in bulk storage applications. Walkie stackers are designed to be used in narrow aisles and are ideal for use in rack storage applications. Rider stackers are designed to be ridden by the operator and are ideal for use in heavy-duty applications.

Electric Pallet Stacker Capabilities

Electric pallet stackers are capable of lifting and moving heavy loads with ease. They are designed to be efficient and convenient, and can save on physical labor. Electric pallet stackers are also designed to maneuver well in small spaces, making them ideal for use in warehouses and manufacturing facilities. Heli pallet stackers and Hangcha are some of the most popular electric pallet stackers available in the market. They come in various capacities and can lift loads up to 1600kg with a lift height of up to 4.8 meters. They are also equipped with lithium-ion batteries that provide long-lasting power.

Operational Efficiency

Electric pallet stackers are a game-changer in the field of material handling and inventory movements, offering a wide range of advantages that can significantly enhance operational efficiency and streamline warehouse operations. Here are some ways how electric pallet stackers can help you optimize your warehouse operations:

Optimising Warehouse Aisles

Electric pallet stackers are designed to operate in narrow aisles, which allows you to maximize your warehouse space and increase storage capacity. With their compact size and versatile design, electric pallet stackers can easily maneuver through tight spaces and lift loads to higher heights, making it easier to stack and store inventory. This means you can store more goods in your warehouse without having to expand your facility or move to a larger location.

Material Handling and Inventory Movements

Electric pallet stackers can help you move materials and inventory more efficiently and safely. With their electric-powered motors, electric pallet stackers can move heavy loads with ease, reducing the need for manual labor and minimizing the risk of workplace injuries and accidents. Electric pallet stackers are also designed for precision and speed, allowing you to move inventory quickly and accurately, which can help you meet customer demands and increase your productivity.

In addition, electric pallet stackers have a versatile design that allows you to handle a wide range of loads, including pallets, containers, and other materials. This means you can use electric pallet stackers for a variety of tasks, from loading and unloading trucks to moving inventory within your warehouse.

Safety and Controls

When it comes to electric pallet stackers, safety and controls are crucial factors to consider. In this section, we will discuss the different aspects of safety and controls that you should be aware of before operating an electric pallet stacker.

Operator Controls and Ergonomics

One of the key features of electric pallet stackers is the operator controls. These controls allow the operator to control the movement of the stacker, including lifting, lowering, and steering. The controls should be intuitive and easy to use, so that the operator can focus on the task at hand.

Additionally, the ergonomics of the operator controls are also important. The controls should be located in a comfortable position, so that the operator can use them without straining or injuring themselves. The controls should also be designed to reduce fatigue, so that the operator can work for longer periods of time without experiencing discomfort.

Durability and Construction

Another important factor to consider when it comes to electric pallet stackers is durability and construction. Heavy-duty construction and durability are essential for ensuring that the stacker can handle heavy loads and withstand the wear and tear of daily use.

The heavy steel frame of the stacker should be designed to withstand the weight of the load, as well as any shocks or impacts that may occur during loading and unloading. The forks should also be designed to withstand heavy loads and should be made from high-quality materials to ensure durability.

Call our team on (02) 7209 0601

Get A Quote NowPurchasing and Ownership

When it comes to purchasing an electric pallet stacker, there are a few key considerations to keep in mind. By selecting the right electric pallet stacker, you can ensure that you have a reliable and efficient tool for your business needs. In this section, we will cover some tips for selecting the right electric pallet stacker, as well as maintenance and long-term care.

Selecting the Right Electric Pallet Stacker

When selecting an electric pallet stacker, it is important to consider your specific needs. Think about the types of loads you will be moving, the distances you will be traveling, and the terrain you will be operating on. Consider factors such as lift capacity, lift height, and turning radius. Also, think about the size and weight of the stacker itself, and whether it will fit in your workspace.

There are many different brands and models of electric pallet stackers available on the market, including forklifts, electric walkie stackers, and pallet jacks. Do your research and compare the features and prices of different models to find the one that best meets your needs.

Maintenance and Long-Term Care

Once you have purchased your electric pallet stacker, it is important to take good care of it to ensure that it lasts for many years. Regular maintenance is key to keeping your stacker in good working order. This includes tasks such as checking the battery, inspecting the wheels and tires, and lubricating moving parts.

In addition to regular maintenance, it is important to take steps to prevent damage to your stacker. This includes avoiding overloading the stacker, operating it on uneven surfaces, and failing to properly secure loads. By taking good care of your electric pallet stacker, you can ensure that it continues to operate efficiently and reliably over the long term.

Financing options are available for those who need them. Contact Liftwise for more information on financing options that may be available to you.

In conclusion, selecting the right electric pallet stacker and taking good care of it are key to ensuring that you have a reliable and efficient tool for your business needs. By considering your specific needs and taking steps to prevent damage, you can keep your stacker in good working order for many years to come

Frequently Asked Questions

Pallet stackers are also commonly referred to as walkie stackers, electric pallet jacks, or pedestrian stackers. These terms are often used interchangeably within the industry.

When choosing to purchase or hire a walkie stacker, consider factors such as the weight and size of the loads to be moved, the height of the shelving or racking, the width of the aisles, and the frequency of use. Other factors to consider include the availability of charging stations, the type of flooring in the workplace, and the budget for the equipment.

Electric stackers, also known as walkie stackers, are smaller and more manoeuvrable than traditional forklifts. They are designed to operate in narrow aisles and tight spaces, making them ideal for use in warehouses and distribution centres. Unlike traditional forklifts, electric stackers do not have a cab for the operator to sit in, and the operator walks alongside the equipment. Electric stackers are also powered by rechargeable batteries, making them more environmentally friendly than their gas or diesel-powered counterparts.

In Australia, a special licence is not required to operate a walkie stacker forklift. However, operators must be trained and certified to operate the equipment safely. It is the employer’s responsibility to ensure that all operators are adequately trained and competent to operate the equipment.

When operating a pallet stacker, safety should always be a top priority. It is important to wear personal protective equipment such as a hard hat, safety shoes, and high visibility clothing. Before using the stacker, make sure that it is in good condition and all safety features are functional. Ensure that the load is evenly distributed and stable on the forks. Always follow the manufacturer’s instructions and the workplace’s safety procedures.